The Creality Ender-3 is a highly popular entry-level 3D printer known for its affordability and impressive printing performance. As part of the Creality family, it offers an open-frame design with a robust V-Slot rail system, ensuring smooth and stable printing operations. Designed for hobbyists and professionals alike, the Ender-3 is widely praised for its ease of use, versatility, and ability to produce high-quality prints, making it an excellent choice for prototyping and creating custom parts.

1.1 Overview of the Ender 3 Series

The Ender 3 series, including models like the Ender-3 V2, V3, and S1 Pro, offers a range of entry-level to advanced 3D printing solutions. These printers are known for their open-frame design and robust V-Slot rail system, ensuring smooth and precise printing. Partially pre-assembled, they come with essential tools for easy setup. The series caters to both hobbyists and professionals, providing high-quality prints and supporting high-temperature printing for intricate details.

1.2 Key Features and Specifications

The Ender 3 series boasts a build volume of 220x220x250mm, supported by a durable OpenBuilds V-Slot rail system for smooth printing. It features a heated bed for consistent adhesion and compatibility with PLA, PETG, and ABS filaments. The printer supports high-temperature printing for intricate details and comes with a user-friendly manual. Its modular design allows for easy upgrades and customization, making it versatile for hobbyists and professionals alike.

Unboxing and Inventory

Your Ender 3 package includes the partially pre-assembled printer, a power supply, a set of tools like a metal blade and cutting pliers, and essential accessories for assembly.

2.1 What’s Included in the Box

The Ender 3 package includes the partially pre-assembled printer, power supply, and a set of essential tools such as a metal blade, cutting pliers, and Allen wrenches. Additionally, you’ll find accessories like belts, screws, and a user manual. Some versions may also include an SD card for firmware updates or sample print files to get you started quickly.

2.2 Tools and Accessories Provided

The Ender 3 comes with a variety of tools and accessories to aid in assembly and maintenance, including Allen keys, screwdrivers, and spare belts. Additional items like a metal blade, cutting pliers, and cable ties are also included. These tools ensure you have everything needed for setup and minor adjustments, making the initial assembly process smoother and more efficient for users of all skill levels.

Assembly and Initial Setup

The Ender 3 arrives partially pre-assembled, requiring minimal setup. Tools like Allen keys and screwdrivers are included for easy assembly; Follow the step-by-step guide for a smooth experience.

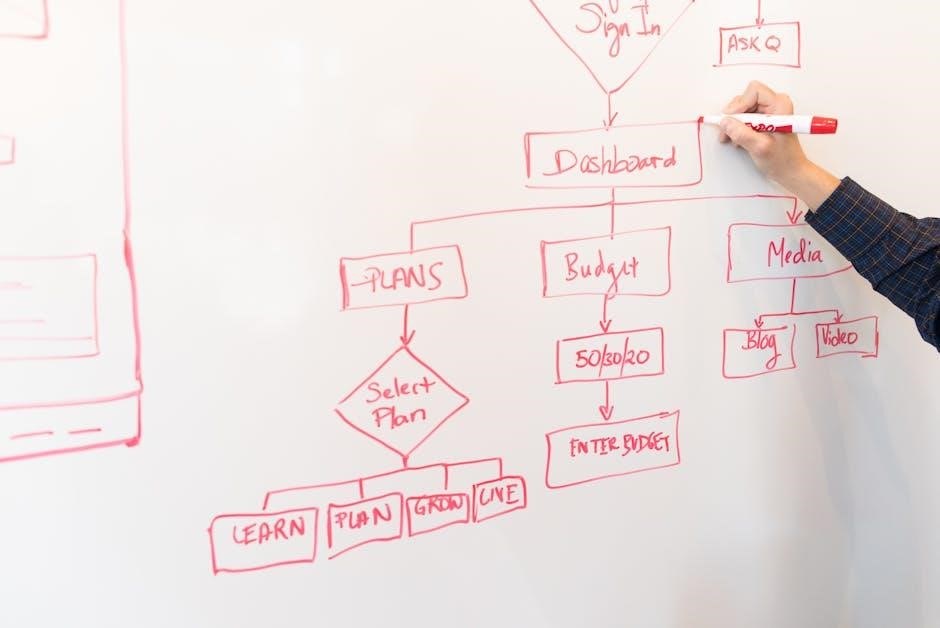

3.1 Step-by-Step Assembly Guide

Begin by unboxing and inventorying all components. Follow the manual’s diagrams to assemble the frame, then install the gantry and Z-axis. Next, attach the extruder and print bed, ensuring proper alignment. Connect the motherboard, stepper motors, and sensors carefully. Finally, power on the printer and perform initial checks to ensure all components function correctly before proceeding to calibration.

3.2 First-Time Power-On and Initial Calibration

After assembly, power on the printer and check for any issues. Navigate to the LCD menu to access setup options. Set the current for stepper motors and home the axes. Perform manual bed leveling by adjusting screws while the printer heats up. Ensure the print bed is clean and secure. Finally, verify all connections and settings before starting your first print job.

Safety Precautions and Usage Guidelines

Always ensure proper ventilation and avoid flammable materials nearby. Keep children away and never leave the printer unattended while operating. Follow manual guidelines strictly.

4.1 Important Safety Measures

Ensure proper ventilation and avoid flammable materials nearby. Never leave the printer unattended during operation. Keep children under 10 years old away and supervise older children. Use protective gear like gloves when handling hot parts. Always select the correct input voltage (230V or 115V) to match your local mains. Avoid overloading the printer and maintain a stable, level surface for operation.

4.2 Usage Guidelines for Optimal Performance

For optimal performance, ensure the printer is placed on a stable, level surface. Regularly clean and lubricate moving parts to maintain smooth operation. Always pre-level the bed before printing and use the correct filament settings for your material. Keep the build plate clean and free of debris. Update your firmware and slicing software periodically for improved functionality and compatibility. Properly prepare the build plate with adhesive aids like boron carbide or glass for better first-layer adhesion. Ensure the printer is used in a well-ventilated area to prevent fumes buildup. Regularly inspect belts and pulleys for wear and tear. Avoid overloading the printer with excessively large or complex prints beyond its capabilities. Use the control panel wisely to monitor and adjust settings during prints. Always refer to the user manual for specific guidelines tailored to your Ender 3 model. Ensure the printer is powered off when not in use or during maintenance to prevent accidents. Keep the printer firmware updated to the latest version for optimal performance and new features. Avoid exposing the printer to extreme temperatures or humidity levels, as this can affect print quality and machine longevity. Regularly check and tighten all bolts and fasteners to ensure stability during printing. Use high-quality filaments recommended for your printer to achieve the best results. Avoid using damaged or worn-out nozzles, as they can degrade print quality. Properly store unused filament in a cool, dry place to prevent moisture absorption, which can affect print quality. Always follow the manufacturer’s guidelines for filament loading and unloading to avoid damaging the extruder or hotend. Keep the printer’s surroundings clean and organized to prevent dust or debris from interfering with its operation. Regularly check the extruder gears for wear and ensure they are clean and free of filament residue. Avoid printing in direct sunlight or near windows, as UV light can affect certain filaments. Always ensure the printer is properly calibrated before starting a print job to avoid wasted material and time. Use the provided tools for adjustments and maintenance to prevent damaging the printer’s components. Keep a log of your prints to track settings and identify areas for improvement. Avoid overclocking the printer or pushing it beyond its recommended speeds, as this can lead to poor print quality or mechanical issues. Regularly inspect the PTFE tubing for signs of wear or damage and replace it if necessary to prevent clogs or leaks. Ensure the printer’s fans are clean and functioning properly to maintain optimal cooling during prints. Avoid using incompatible or third-party parts that may void the warranty or compromise performance. Always follow the recommended temperature settings for your filament to prevent overheating or under-extrusion. Keep the printer’s firmware updated to ensure compatibility with the latest slicing software and features. Regularly clean the print head and extruder to remove any debris or old filament residue. Avoid leaving the printer unattended during the first few layers of a print to ensure proper adhesion and prevent failures. Use the provided SD card or connect via USB for reliable file transfer and printing. Ensure the printer is grounded properly to prevent static electricity issues. Avoid using abrasive cleaners on the printer’s surfaces, as they can damage the finish or harm electrical components. Regularly check the power supply for stability and ensure it is rated for your printer’s power requirements. Keep the printer away from pets and children to prevent accidental damage or interruption. Always refer to the user manual for troubleshooting common issues before attempting advanced repairs. Use the recommended slicing software settings for your specific Ender 3 model to achieve consistent results. Ensure the printer is properly calibrated after any upgrades or modifications to maintain accuracy. Regularly inspect the belts for tension and alignment to ensure smooth and precise movement. Avoid using low-quality or counterfeit components, as they can compromise print quality and safety. Keep the printer’s surroundings quiet and free from vibrations to ensure stable operation. Always follow proper safety protocols when handling electrical components or performing maintenance. Regularly update your slicing software to take advantage of new features and improvements. Ensure the printer is used in an environment with consistent temperature and humidity levels to maintain print quality. Avoid printing in areas with high dust levels, as this can affect the printer’s components and print quality. Regularly check the hotend for blockages or debris and clean it as needed to ensure proper extrusion. Use the provided documentation and online resources for troubleshooting and optimizing your printing experience. Keep the printer’s firmware and software up to date to ensure the latest features and security patches are installed. Avoid using incompatible filaments that may damage the hotend or extruder. Regularly inspect the build plate for wear and ensure it is properly secured to the printer. Use the recommended adhesion aids for your filament type to achieve the best first-layer adhesion. Avoid over-tightening or under-tightening belts and fasteners, as this can affect print quality and machine stability. Regularly clean the printer’s exterior and interior to prevent dust buildup and maintain performance. Ensure the printer is properly configured in your slicing software to match its specifications and capabilities. Avoid using damaged or curled build plates, as this can lead to poor adhesion and print failures. Regularly check the extruder’s gear teeth for wear and ensure they are clean and free of debris. Use the recommended retraction settings for your filament to prevent oozing and stringing. Avoid printing in areas with strong drafts or airflow, as this can affect cooling and print quality. Regularly inspect the PTFE tubing for kinking or damage and replace it if necessary. Ensure the printer’s fans are set to the correct speeds for your filament type to maintain proper cooling. Avoid using low-quality or damaged SD cards, as this can cause printing issues or data corruption. Regularly check the printer’s power cord for damage or wear and replace it if necessary. Keep the printer’s surroundings organized to prevent cables or filaments from getting tangled or caught. Use the provided tools for leveling the bed to ensure accuracy and prevent damage. Avoid leaving the printer exposed to direct sunlight or moisture, as this can affect its components and print quality. Regularly inspect the printer’s frame for stability and ensure all fasteners are secure. Use the recommended filament guides to prevent tangles or twists during printing. Avoid using incompatible or oversized nozzles, as this can affect print quality or damage the hotend. Regularly check the printer’s belts for proper tension and alignment to ensure smooth operation. Use the provided documentation to understand the printer’s components and functions for better maintenance and troubleshooting. Ensure the printer is used in a well-lit area to monitor prints effectively and make adjustments as needed. Avoid using abrasive materials on the build plate, as this can damage its surface and affect adhesion. Regularly inspect the printer’s electrical connections for wear or damage and ensure they are secure. Use the recommended software settings for your filament type to achieve optimal results. Keep the printer’s surroundings clean and free of clutter to prevent accidents or damage. Regularly check the printer’s firmware version and update it if necessary to ensure the latest features and improvements. Avoid using the printer near open flames or sparks, as this can pose a fire hazard. Use the provided safety guidelines and precautions to ensure a safe and enjoyable printing experience. Regularly inspect the printer’s components for wear and tear, and replace them as needed to maintain performance and safety. Ensure the printer is properly configured and calibrated after any upgrades or modifications to ensure optimal performance. Avoid using low-quality or counterfeit filaments, as they can compromise print quality and safety. Regularly check the printer’s build plate for proper leveling and adhesion before starting a print. Use the recommended slicing software profiles for your Ender 3 model to achieve consistent and high-quality prints. Avoid leaving the printer unattended during long print jobs, as this can lead to unexpected issues or failures. Regularly clean the printer’s fans and heat sinks to ensure proper cooling and prevent overheating. Use the provided documentation and online resources to stay informed about the latest updates and improvements for your printer. Ensure the printer is used in a stable and secure environment to prevent accidents or damage. Avoid using incompatible or third-party software that may void the warranty or compromise performance. Regularly inspect the printer’s wiring and connections for wear or damage and ensure they are secure. Use the recommended maintenance schedule to keep your printer in optimal condition and ensure longevity. Avoid printing in areas with high humidity or moisture, as this can affect the printer’s components and print quality. Regularly check the printer’s extruder for proper function and ensure it is clean and free of debris. Use the provided guidelines for loading and unloading filament to prevent damage or clogs. Avoid using the printer near strong magnetic fields or sources of interference, as this can affect its operation. Regularly inspect the printer’s frame and components for stability and ensure all fasteners are secure. Use the recommended settings and guidelines for optimal performance and to achieve the best possible prints. Avoid leaving the printer exposed to extreme

Choosing the Right Filament

Selecting the right filament ensures optimal print quality and durability. Common choices include PLA, ABS, and PETG, each suited for different applications and printer capabilities.

5.1 Recommended Filament Types

The Ender 3 supports a variety of filament types, including PLA, ABS, PETG, and wood-filled options. PLA is ideal for beginners due to its ease of use and minimal warping. ABS offers higher durability but requires a heated bed. PETG combines strength and flexibility, making it suitable for functional parts. Experiment with different materials to achieve desired print characteristics and durability.

5.2 Loading and Unloading Filament

Load filament by preheating the bed and extruder via the LCD menu. Insert the filament into the extruder, gently pushing until it feeds through. For unloading, navigate to the “Filament” menu, select “Unload Filament,” and let the printer retract it automatically. Always ensure the bed is cool before handling filament to avoid damage or injury. This process ensures smooth material changes and prevents clogs.

Bed Leveling and Calibration

Bed leveling and calibration ensure precise print quality by aligning the print bed with the extruder. Proper calibration guarantees consistent first-layer adhesion and successful prints.

6.1 Manual Bed Leveling Process

Manual bed leveling is essential for ensuring even adhesion of the first print layer. Start by powering on the printer and preheating the extruder. Adjust the bed leveling screws located at the four corners of the print bed to lower or raise it. Use a piece of paper to check the gap between the nozzle and the bed, ensuring it’s evenly tight across all corners. Once aligned, tighten the screws firmly to secure the bed in place. This process ensures optimal print quality and prevents issues like warping or uneven layers.

Upgrades and Customizations

6.2 Automatic Bed Leveling (if supported)

Automatic bed leveling simplifies the calibration process, ensuring precise and consistent results. If your Ender 3 model supports this feature, activate it via the control panel or firmware settings. The printer automatically adjusts the bed using sensors like BLTouch, detecting and compensating for surface irregularities. This feature enhances printing accuracy and saves time, especially for users seeking convenience and optimal first-layer adhesion.